Happy Holidays!

Wishing friends and colleagues a very merry Christmas and a prosperous and successful New Year.

For those of us who are fortunate, it’s a time to relax and refresh with friends and family.

However, many people struggle at this time of year for a whole variety of reasons.

For that reason, as I usually do, instead of cards I will be making a donation to Oakleaf who help and support people less fortunate than many of us. https://www.oakleaf-enterprise.org

If you can support them in any way please do.

Thank You

Thames Valley Deals Awards 2025

I was honoured to be invited to be an Independent Judge for the recent Thames Valley Deals Awards for 2025. The dinner was held at the Select Car Leasing Stadium, home of Reading FC.

This was a new experience for me as my previous judging had been in the South East region, which I think went back to 2016 when I was Regional Chair of the IoD and went on up until 2023.

Apparently Farnham, where I live, is in the Thames Valley for the purposes of these awards, so theoretically I was on my home patch!

It was really interesting to learn about the Deal and M&A activity on another patch and find out who were the leading players and what was different about this region.

On the evening itself I presented two awards

Firstly to BDO for the Transaction Services Team of the Year award. A great night for them as they scooped a series of awards!

https://www.insidermedia.com/galleries/thames-valley-deals-awards-2025/image#9

And secondly to Jack Griggs of James Cowper Kreston Corporate Finance for the Emerging Dealmaker of the Year, always a nice award to judge seeing how young talent is emerging.

https://www.insidermedia.com/galleries/thames-valley-deals-awards-2025/image#12

A summary of the event, listing all of the shortlisted and winners can be found here

Many thanks to The Business Magazine and Insider Media teams for all of their great work in facilitating the judging and running the event- everything was first class.

Also to host Mark Durden-Smith the host- I hope that the ‘Chicken slayer’ moniker doesn’t stick!

Joining the Team at Stroud International

I’m very pleased to be joining the Stroud International team as Strategic Advisor.

Stroud International is a specialised operations improvement firm working in both manufacturing and capital projects sectors.

Working across Europe, USA and Canada it helps companies solve their highest impact problems and deliver lasting improvement to costs, capacity and quality.

With experience of facilitating projects in sectors as diverse as food & beverage, plastics, ceramics, health and personal care, chemicals, machining, furniture and high end motorsports, Stroud is familiar with the needs of both high and low volume industries.

“The team at Stroud International is delighted to have David Seall supporting our mission to unleash the potential of UK manufacturers – helping them to achieve rapid, real improvement in their operations.

David’s deep understanding of the UK manufacturing landscape means he is uniquely placed to help us shape and target our support where it will create the greatest value for the sector.”

The team work with the shop floor in an intensive methodology to deliver swift returns on investment and longstanding productivity gains. https://www.stroudinternational.com

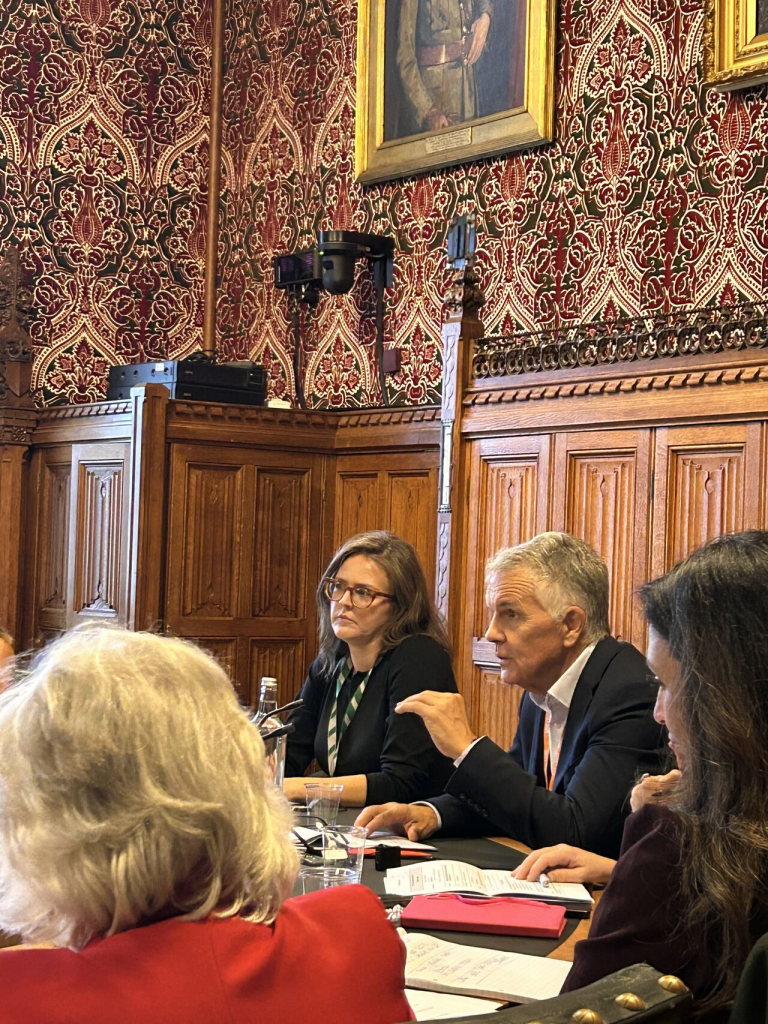

Another day in the Houses of Parliament- In the Lords this time

I was back in the HoP this week for an evidence session for the Manufacturing Commission’s inquiry into the Government’s Industrial Strategy this time concerning ‘Access to Finance’.

The session was chaired by Lord Bilimoria, always a great supporter of UK Manufacturing.

we were very fortunate to be joined by representatives of the British Business Bank who outlined how they will be supporting the Government’s Industrial Strategy and providing investments to finance growth.

We were also joined by EMC Corporate Finance’s Michael Gibbs in what was a lively session exploring many areas that stifle UK Manufacturing in fulfilling its potential.

We covered areas such as raising finance for capital investment (always an issue for manufacturers), accessing grant income, the R&D Tax Credit and working with banks.

Solving the skills conundrum

I was back in Parliament recently to attend a round table meeting to discuss the progress of Skills England after its first year.

It was a vibrant and challenging session with some tremendous contributions from the participants.

After 30 years of working in and around the skills sector it still remains a mess particularly in Higher and Further education. However Skills England under their inspirational Chair Phil Smith are getting a grip on things, asking the difficult questions and focussing on what really matters. I left the meeting feeling very encouraged.

Greening the economy and how manufacturers can make the future more sustainable

A few years ago I put together a blog about some chapters had written for some books. You can find the post here

The chapters were a great way to focus my brain during those troubled times of lockdown and the post-lockdown/2nd lockdown confusion. The good thing is that those times now seem an age ago.

I was obviously pre-occupied with this issue as I posted again here and here

Also some time ago I wrote about the servitization of manufacturing and what the impact would be.

Following the interview I gave to New Street Group during the summer it made me think about those original chapters which you can find below.

You can purchase the books here and here and I would highly recommend them.

It’s interesting that this very week Make UK published a paper about capitalising on Green Technologies

How the UK manufacturing sector can grasp the opportunities of new technologies and contribute to future sustainability

This chapter details some of the challenges that the manufacturing sector within the United Kingdom currently face and how by embracing Industry 4.0 along with other exciting technologies can create a truly circular economy.

The greening of the United Kingdom’s manufacturing economy has been underway for at least the last 25 years. It began with the push to outsource labour and energy intensive manufacturing processes to Central and Eastern Europe and China and the Far East at the end of the twentieth century. Large corporations sought to benefit from cheaper products and wanted reduced labour costs and were keen to build relationships with these growing economies to create new markets for their goods. They also wanted to reduce exposure to taxation, such as the poorly focussed Climate Change Levy in the UK and remain globally competitive.

The carbon footprint of the UK reduced significantly and even the recycling of our waste was outsourced. However, our imported carbon footprint rose in proportion and thus the UK failed to reduce the true effect of our activities.

The unprecedented economic disruption caused by COVID-19, uncertainty surrounding Brexit and the growing realisation of the catastrophic effects of climate change, have accelerated the need for the UK to revisit and change the way we consume and also produce the goods that we need to become globally competitive and create essential resilience in our economy.

These disruptions have emphasised that global, highly stretched, long distance supply chains have struggled to demonstrate resilience and even cross-channel supplies can no longer be guaranteed. Supplies of pharmaceuticals, medical equipment and food are now seen as vulnerable and the manufacturers of these are seen as strategically essential industries that should be based in the UK. Hence the increasing demand for re-shoring and the domestic production of critical products and services. This will inevitably lead to the potential for our own greenhouse emissions to rise with the increasing productive activity.

To mitigate this, it will not be adequate to go back to the old ways of production. Manufacturing industry needs to grasp the opportunities of using new energy sources, improved processes and less intensive consumption of resources.

The impact of Industry 4.0 (which has been defined and explained in a multitude of sources), cannot be underestimated within this more strategic approach. The impact will be demonstrated in a number of key areas.

Supply Chain

It has been found that the supply chain contributes a significant contribution to an Original Equipment Manufacturer’s (OEM) total carbon footprint. One global pharmaceutical manufacturer recently claimed that nearly 25 per cent of its carbon footprint was produced by the activities within its supply chain. The Industry 4.0 requirement for the digitally automated management of suppliers by the OEMs can lead to a more resilient and efficient system. The just-in-time production and delivery of components and parts will be finely honed and efficient. Over production and inventory will be minimised and the sources of production will be disaggregated from the current single sources and will be located closer to the point of demand. This will reduce the distances of parts travelled and make the shipping of container loads of ‘stuff’ less desirable. This reduction in transportation can also significantly reduce the carbon footprint of the products.

Additive manufacturing

Localised production can be made even more efficient by the use of additive manufacturing otherwise known as 3d printing. This is very ‘pull focussed’, whereby set up times and specific tooling requirements are minimised and only the parts needed at the time need to be produced. The only inventory required is the raw material whether metallic or polymer based and this can be used across a range of parts. Additionally, parts produced tend to be more structurally efficient and consequently are lighter too. Porsche has recently developed an electric transmission casing additively manufactured in aluminium that is ten per cent lighter than the previous conventionally cast component. This technology enables these parts to be made near the point of use without the transportation and storage of finished parts. In theory these parts or parts like them could be produced at service and support centres. A case in point is that of Mercedes Benz which has already introduced 3d printers to print polymer parts in some its truck support centres in the USA.

Servitization

Another aspect of Industry 4.0 that will have a significant impact on the efficient use of resources is the advent of servitization. This is where the manufacturing company is not only responsible for the manufacturing of the part or assembly, it is also responsible for the full support of the product through the entire service life of that product with the customer.

We see this manifested at the moment with the Rolls Royce Aero engine model where airlines no longer buy engines but buy a service for the delivery of power from Rolls Royce, sometimes on an hourly basis. Rolls Royce maintain those engines and ensure optimum performance being rewarded with a long-term income stream for a fixed time period.

Those that buy their mobile phone service through a contract get a similar sort of service. Increasing responsibilities are placed on the supply chain to be both capable of providing in-service support but also to look at careful through life cost management. This means that reducing costs during manufacture, at the expense of longevity, is not in their best interests.

An example of this would be the bus companies, who instead of buying the cheapest tyres for their fleet, move toward a service contract based on mileage of their buses. This drives the contractor to purchase the best tyres that not only have a longer initial life but because of superior carcass construction, these tyres can be re-treaded or “re-manufactured” two or three times. This reduces the overall environmental impact by reducing energy consumed and ensuring that materials remain in use and do not contaminate the environment.

This servitization model will move from B2B to B2C. Customers will use Internet of Things connected devices such as phones, TVs, domestic goods and cars and pay for the service – either via a pay as you go or by subscription. These products will know when to be serviced and will call out for the delivery and fitting of replacement parts. An autonomous vehicle may even drive itself to the service depot for overnight repair.

Servitization also drives designers to create less modular designs which are then easier to repair in service. The adoption of ‘right to repair’ legislation across Europe encourages manufactures of consumer goods to build in repairability and reduce the modular, hard to replace and thus expensive nature of the componentry. Again, as we move from an ownership model to one of hire or rental, the onus moves to the supplier of goods to think long term about the relationship and support of the customer. It could be that the customer has a broom that has served them well for ten years but has had five handles and ten heads constantly maintained by the supplier!

Materials optimisation- Technology, Recycling and Remanufacturing

All of this means that the utilisation of materials is optimised, waste is not produced, either during the manufacturing process or at the end of life of the product as there is a much reduced need for landfill.

Alongside this is the search for more sustainable materials that require less energy to produce and also have less reliance of fossil fuels and other natural resources. Plastics sourced from organic sources such as sustainable sugar cane can be used. There have been significant moves to create more sustainably sourced composite materials using organic resins and natural fibres. For example, this has been regulated in some forms of motorsport for non-critical structural components thus avoiding the need for carbon fibres and epoxy based resin systems. These materials are less harmful for the environment at end of use. Even with conventional epoxy/carbon composites, waste materials and recycled parts are being remanufactured into other products, an example being carpet tiles for future Boeing aircraft. It has been said that a tonne of mobile phones has more gold within it than a 100 tonnes of ore. Recycling and remanufacturing will create a circular economy which will optimise the use of all materials, especially those that are expensive and strategically difficult to source and ensure that they remain in use without damaging our environment through disposal.

Energy

Underpinning the greening of manufacturing within the UK has to be the efficient use of energy and the use of renewables. The full electrification of industry needs to be incentivised and we must move quickly. Removing gas from the equation particularly when used for heating and especially ovens, needs to be addressed, perhaps by hydrogen conversion. With gas 25 per cent cheaper than electricity it’s difficult to create a business case within an SME to change. In fact, this will be exacerbated when global demand reduces for fossil fuels at the end of the decade, when oil prices are predicted to drop to $20 a barrel. Economically viable and sustainable methods of producing and distributing hydrogen as an alternative fuel will need to be determined. Also, factories creating their own energy though solar panels and perhaps small wind turbines will only be viable if that energy can be stored and used within the factory. Cost efficient technology such as cheaper, heavier sodium batteries or even mechanical flywheel based technologies may be the answer.

Skills

All of this new technology such as digitisation, servitization, supply chain management, new materials and green energy needs an upskilled workforce to enable this step forward. Manufacturing is in a competitive environment to capture these skills as they are in demand from many other sectors such as finance, business services and retail. A revitalised manufacturing sector needs to be able to train and secure this talent.

Policy

There is also a massive strategic gap in capabilities and awareness between the OEMs, at the top of the supply chains and the small and medium sized enterprises (SMEs) at the bottom. The OEMs, driven by their Boards and shareholders to address the issues of Environment, Sustainability and Governance (ESG) are funded and mandated to tackle these issues head on. Whilst the supply chain SMEs, which constitute a significant percentage of the total environmental footprint of an OEM, struggle to find the funds, skills and even management time to address these issues. Greater support to SMEs is going to be required to address the issue, especially as more of the supply chain will now be UK based. Support with skills, advice, technology and especially intelligent procurement and funding will help.

We will also need careful guiding of the energy market to encourage further electrification and the roll out of hydrogen for both combustion and use in fuel cells.

Underpinning this is a strategic approach from Government that can create the climate for success. This involves addressing the key skills shortages, encouraging the use of more sustainable materials and most importantly determining a strategy for future industrialisation which creates resilience with export potential that has sustainability at the core.

And the second chapter

Organisation, processes and skills and their future impact on sustainable manufacturing

As we move forward towards a future net-zero, with sustainability integral to all operational activities, manufacturers find themselves tackling the objective on several fronts.

Those within supply chains are increasingly facing contractual obligations and measures to improve sustainability, as the larger Original Equipment Manufacturers (OEMs), face scrutiny of their environmental impact.

Companies find themselves under greater external pressures to meet environmental, social and governance (ESG) mandates. Politicians, lobbying groups and the media continue to fuel the appetite of investors and informed consumers. The expectation is that manufacturers must do all that they can to create a more sustainable future for manufacturing and quickly.

Rules of origin for the constituent materials and components of finished products are not only important for post-Brexit trading regulations. There is also a growing expectancy from consumers that materials will be sourced ethically in a fully traceable and measurable manner. Manufacturers are no longer only responsible for the carbon footprint of their own operations but also for the greater impact of their total supply chain.

As expected, there will be a gradual flow down of the requirements of reporting and measurement into the supply chain and down to the level of the small and medium sized enterprise (SME).

Organisation

Organisationally there are several major challenges that these businesses face. Amongst these are governance, culture, leadership, strategy, and maintaining customer and supplier relationships.

The boards of many companies have realised that their duties are no longer to the shareholders alone but also to a multitude of stakeholders. Of course, it could be argued that failing to meet environmental targets will not only adversely affect many different groups but also lead to a corresponding negative impact on the share price. It will consequently lead to further downstream costs as OEMs will be subjected to legislations making them accountable for lifetime product lifecycle impacts, emissions and consequent recycling. Landfill and waste finding its way into the ocean will no longer be tolerated.

Aligning the organisation to ensure that the objectives are met requires full commitment from the board, inspired leadership and a creation of a strategy within the business that is not stand alone but is complementary to other activities, this must be integral within business operations and business management systems.

If this is successful it can create a culture within the organisation where everyone is committed to achieving a truly net-zero enterprise. This would also be guided by the behaviours of customers and consumers.

Processes

When we look at processes is it’s quite clear that the adoption of lean manufacturing and the future opportunities of Industry 4.0 have and will aid, the reduction of waste and future sustainability of manufacturing.

Indeed, many companies that have not adopted these systems have implemented design control rules to control and reduce variation within product designs. This manifests itself for the designer with a restricted choice of both materials and processes and consumable items such as adhesives, sealants and fasteners. This can be used to further restrict choice to specify more sustainable options and reduces unused stock.

The impact of regulations such as Waste from Electrical and Electronic Equipment (WEEE) and the ‘Right to repair’ have further influenced designs to focus on recyclable materials and products that have greater modularity. These regulations and systems mean that the future emphasis on product design must embrace materials that are ethically obtained from a sustainable or recycled source and have eventually a net-zero impact on the environment and have the capability to be recycled and remanufactured into something else. Indeed, the recycling of waste or surplus materials back into feeder stock for new products or into local energy capture is within the control of the manufacturer.

Manufacturers may also produce sub-assembles with inherent design features that enable them to be repaired. Of course, eventually this approach can lead to the servitization (an integral part of Industry 4.0) of the product where the onus on repairability is with the OEM. Instead of selling a product, they are selling a service to the consumer based upon the reliability and serviceability of the product throughout the product lifecycle. For example, a smartphone or a car hire/leasing service.

Thus, it is in the manufacturer’s interests to design a product that is built to last and can be repaired or that can be refurbished, rather than one that will be thrown away within a short time.

The consumer has a growing appetite for ‘remanufactured’ products that have full service lives and perhaps can be adapted and repurposed to meet a different need at some time in the lifecycle. A growing group of consumers also want to be able to repair products themselves.

When considering lean manufacturing, the universally adopted Toyota Production System names the following wasteful activities or ‘muda’ that need to be tackled within factory and service operations

- Transportation of products and materials unnecessarily

- Overproduction- making too much

- Waiting and delays

- Defects and consequent rework

- Inventory and manufactured products that aren’t used

- Movement of people

- Extra-Processing that isn’t required to meet customer requirements

- Unused talent

The reduction of many of these wastes will contribute to a more sustainable future. Manufacturing only what is required, correctly and efficiently without using resources to correct faults is obviously compatible with using fewer resources and less energy.

It does however emphasise the core reasoning for ‘lean’ being the reduction of non-value adding activity (waste) across the board, rather than the common misconception used by so many businesses of driving cost out, reducing overheads and employing ‘time and motion’ techniques to ‘sweat’ assets.

For many years the focus on these wastes has been within the boundaries of the organisation itself. Organisations have perhaps ignored the impact on the environment of increasingly stretched supply chains. This has led to large stock consignments and raw materials travelling thousands of miles by sea to supply domestic factories. It has been a major contributor to global emissions. Also, many larger OEMs are well known for shifting so called ‘buffer’ stocks on to their suppliers to provide some contingency for their own ‘Just in time’ operations. If looked at in simplistic terms, things are not as ‘lean’ as they could be and wasteful activities have merely been displaced.

However, the global pandemic and increasing resistance to globalisation from populist administrations across the world, has resulted in companies increasingly looking to ‘reshore’ production closer to the multiple points of demand. In doing this they create locally based supply chains that are more resilient to shocks and have the benefits of shorter lead times. Re-using materials within the local environment instead of importing virgin material and optimising material usage and energy consumption within processes makes economic sense.

Industry 4.0 technologies such as additive manufacturing, are reducing supply chains by enabling parts to be produced close to final assembly operations and not in remote facilities. This reduces the need for the transport of parts over long distances and the associative logistical complexities. Compared with conventional subtractive manufacturing processes such as machining, the waste of semifinished material, (which cost energy to produce) lost during the machining process is nullified by additive manufacturing. Another benefit is that only the material required to manufacture the part is used during the process thus drastically reducing material usage. Also, the increased optimisation and mechanical performance of designs facilitated by this process means that material usage and number of parts in the finished product is minimised. This yields weight savings that can reduce energy consumption for the life of the product, particularly in transportation.

De-risking has gone even further for some with a greater emphasis on on-site production and storage of electricity. South facing factory roofs, originally designed to let in natural light, have become the ideal site for solar panels. An adjustment to move intensive energy activities from the early and later parts of production shifts, when daylight can be low, to during the day time and the storage of this electricity on site rather than feeding back into the grid, is a move toward self-sufficiency and independence of supply.

Eventually the results of the implementation of these processes will be proved when judged against suitable measurement criteria. As the old adage in manufacturing goes ‘if you can’t measure it, you can’t manage it’. If the new processes are managed within a lean manufacturing system, then some auditable results can be obtained. Likewise, within the introduction of a data driven industry 4.0 implementation programme.

However, purely net-zero focused measures such as reduction of energy and water consumption or reducing transportation distances, only go some way toward finding out the total impact of this work. Finding further information embedded in within the supply chain and the original sourcing of raw materials is more problematic. OEMs will be looking in the future for data within their supply chains as many are finding that the supply chain is responsible for a sizeable proportion of their total emissions. Industry 4.0 and blockchain technology should enable an auditable chain of data to help with this.

It’s clear that this data ensures that activities aimed at achieving net-zero demonstrate that they are not only effective but that they are financially beneficial for the organisation. It’s essential that the business can achieve some sort of contribution to the bottom line within a reasonable time. Long term Government incentives to invest in appropriate technologies, provide tax incentives to drive the right behaviours and penalise those that are slow to change can always help with this. A national strategy for the replacement of methane gas with hydrogen, especially ‘green’ hydrogen, will make a major contribution to this. However, it’s not wise for businesses to chase at net-zero and then find themselves unviable.

Skills

The movement toward sustainable manufacturing requires an upskilling of the current workforce. One can see this happening in the automotive sector, where the move away from the internal combustion engine and toward electrification has been happening at breakneck speed. Some of this re-skilling involves the dusting off of some seldom used skills and adapting those to the new requirements.

What is refreshing, is that moving forward, the drive to sustainable manufacturing is a clarion call to those entering employment or deciding on career choices. There is an energy toward sustainability akin with the ‘space race’ of the fifties and sixties. For those that would not have considered studying STEM (Science, Technology, Engineering and Mathematics) subjects or following a technical or engineering based career, there is an opportunity to make a real difference in tackling a problem for all of humanity.

In conclusion, creating a sustainable manufacturing sector will not be an isolated initiative. It’s about the sector showing leadership, commitment and achieving congruency with existing programmes such as lean, digitisation, servitization and Industry 4.0 to ensure a productive and sustainable future.

I’m sending my Tesla back early and here’s why

Nearly three years ago a good friend of mine who works for a major vehicle leasing firm alerted to me to a great offer to lease a new Tesla. We are members of the same cycling group and we’d had conversations before about leasing as I had had my eye on a Tesla Model Y.

I had been thinking about taking the plunge and leasing an electric car for some while but had been hesitating and waiting for a modification to the suspension on the Model Y as the first cars were known to have quite a ‘crashy’ ride (more about this later). Yes I know it’s a bit of an engineer nerdy thing but it’s the way my brain works.

The deal was for a new model on the range, a rear wheel drive car with a ‘standard’ range which is around 57 kwh equating to around 230 miles. This car had the suspension modifications to improve the ride from that of the first cars.. I had really wanted the longer range battery with 4wd but the cost of those cars was quite prohibitive at the time and this was too good an offer to miss.

So I completed all of the paperwork and took possession of the car at Southampton Docks on New Year’s Eve 2022. The car was fresh off of the ship from China (I was told that Chinese cars at the time had the best build quality of any Tesla cars)

So now I’m coming to the end of the lease and I’d like to reflect on my experiences with the car and why I’m sending it back early.

Things I liked

- The Tesla supercharging network– this is an amazing integrated system which means effectively that there is no such thing as range anxiety. It connects continuously with the car to

- Map your journey

- Tell you where you need to stop

- Tells you how much charge you will have when you get there

- Has fast 250kw chargers. The charging speeds are slower when you start and then start to tail off down to around 50-70kw when your battery gets over 80% charge. It’s a bit like watching the final stages of an old fashioned disk defrag on windows.

- Ensure a bay is available for you to use- owners of cars which are fully charged are penalised by a charge on their credit card if they leave the car connected. Occasionally at peak times limits of 65-80% charging are in place.

- To run the system optimally it seems Tesla want you to charge ‘little and often’ to free up capacity and get you moving

- Only once have I arrived at a Supercharger station to find that all of the charging bays were full and that was at Eurotunnel Calais. Within five minutes a bay was available

- The smaller battery size wasn’t a significant problem

- It almost perfectly matched the capacity of my bladder!

- In the summer I usually got 200 plus miles nearer 220 with gentle driving

- In the winter it would go down to 170-180

- Being an LFP battery charging to 100% at home was the norm

- I understand that Tesla source this battery from BYD so that’s a problem for Tesla moving forward

- After nearly three years of driving , including over 6000 miles of Supercharging, the battery still charges to 100%

- The car was ridiculously cheap to run via home charging overnight- We also have solar and batteries at home which helps reduce bills further

- The customer support is fantastic both online and at the local service station. It’s a highly automated process and for some faults, I had an annoying rattle coming from the rear view mirror, this was fixed at home. The guys at the Shalford Tesla centre were great. Other brands could learn a lot from this.

- Tyre wear was normal compared to an ICE car- don’t believe the rubbish in the Daily Fail.

- Performance is blistering– in fact I usually drove in ‘chill mode’. The instant power delivery enables you to accelerate out of awkward situations

- One pedal driving with auto regeneration is great and the brakes themselves had great stopping power and show no signs of ‘grabbing’, however regeneration doesn’t come into play when the battery is at 100% so be careful!

- Steering is direct and the car is enjoyable to drive on B roads

- The control screen in the car has sensibly set out menus and shortcuts, so one isn’t distracted as much as one would think. There are lots of ways to set the car to your own requirements.

- The speed indicator is easy to see and not too far away from your driving eyeline. The size of the font was increased and that was an improvement.

- The semi auto drive mode was amazing meaning long distances and the M25 were not a problem- my son managed to turn the screen into ‘Super Mario’ mode when this was on so it was easy to remember!

- Sentry mode is great when parking the car giving you complete surveillance of the vehicle from your phone – but eats battery when left on overnight!

- The seats were comfortable and the interior space is impressive with plenty of head and leg room

- The space inside with the ‘frunk’ and below boot floor recess meant it was a pretty cavernous car for long trips with loads of safe stowage spaces

- The car was so easy to drive on long trips abroad– two trips to Austria for skiing, a trip to the French alps and a tour of Germany and Switzerland – all pretty effortless

- Charging in France is generally very good.

- Tesla gave me 5000 free miles to use at Superchargers and then gave another 1000 on top of that

- Software updates were frequent and easily done. The car is now a better car than when I got it with some major upgrades and features. In fact one could argue that the Tesla is more of a computer on wheels than a car. All of the systems are very intuitive and easy to use.

- The panoramic sun roof gave a lovely natural light in the cabin

- Remotely pre-conditioning the car at home from the phone to heat the interior and warm the battery was very useful in the winter

- There’s loads of stuff on the screen for entertainment like YouTube and Netflix although I rarely used this.

- ‘Dog mode’ is a very clever idea to enable you to leave pets in the car.

Things that aren’t so good

- The car is Insurance Group 50 so be prepared for a big quote!

- It has the turning circle of HMS Vanguard (google search that) It’s incredibly difficult to manoeuvre with a useless turning circle (I think that this has been improved on the facelifted Model Y)

- The car is also very wide- you leave it in car parks at your peril

- The quality of the paint is thin and poor. I had an optional metallic paint (which then became the standard, meaning that my BIK was above what it needed to be) It just seemed to attract dirt and dust more than the paintwork on a quality car should despite using high quality shampoos and waxes.

- Body panels feel incredibly thin- ditto car park spaces again

- The auto-wipe of the windscreen relies on the cameras- rather than a $1 sensor which Elon Musk refuses to pay for- it doesn’t work!

- The ride is still very firm and on some surfaces very poor vibrations and harshness. The extra weight of the Model Y body on the Model 3 floorpan is crying out for an air suspension option ( I drove this on a Model S years ago and it was amazing) I do understand that the facelifted Model Y does go some way address this apparently

- The cabin quality is ok but not quality, the carpets are rather ‘brillo pad’

- The rear parcel shelf is cheap and nasty as is the removeable floor panel

- The sharp throttle response can make some passengers feel car sick– particularly in the back

- When the car was collected I found out that there were no parking sensors (another Musk cost cutting mandate) after a wait and then three different upgrades the solution was delivered using cameras. This works very well but surely this should have been an augmentation to the parking process rather than a replacement?

- There’s no Apple Car Play or Android which may frustrate some.

- The Supercharger cables are only long enough to charge cars with charging points either on the passenger side rear or driver side front. Non Tesla cars which have ports elsewhere on the car take up two bays

- On newer cars the shifter stalk has been removed and the wiper function moved to the screen just leaving an indicator stalk. Another cost cutting measure that just grates with me.

- New cars also now no longer supply a charger that connects to a 13 amp plug, it’s an extra.

- Roof bars have to be fitted at a dealer and then remain on the car- those fixing them at home run the risk of cracking the glass roof. This is a bit of a pain for someone like me who likes to carry bikes on the roof.

- No idea why the adverts on Spotify sometimes were for an American audience!

So what’s the overall verdict on the Tesla?

Despite the shortcomings I’ve mentioned, in the overall scheme of things it has been a great car.

I have enjoyed driving it and became a real ‘Tesla bore’ explaining to anyone who will listen how great it is. I would highly recommend the brand as an entry car into the EV way of life, particularly if you fear range anxiety. The Tesla Supercharger Network system is superb particularly in the UK where we don’t yet have the charging infrastructure of countries like France. In comparison with regularly filling up with fuel, charging at home is just so good. The car is always fully charged and ready to go. The average stop at a Supercharger is roughly 20-25 minutes with time to stretch the legs, use the loo, buy a coffee and catch up on a few emails. I don’t think that takes much longer than using a fuel station and then parking again and walking to the services.

Despite at one point thinking that my mileage would be getting close to the maximum, I now find It’s significantly under.

Over the last six months I have been evaluating the cars are in this family SUV market and to nobody’s surprise, there are a lot!

I think that with the speed of innovation and the constant introduction of new models and makes in this sector leasing makes good sense.

One thing I have learned when leasing a car is to look for deals where manufacturers have made a big batch of cars to a certain specification and then put them into the leasing system. This is where one can get real value for money. Building your own car to a specific spec negates that benefit and also means that you will probably have a long wait time- I was quoted 32 weeks for one car.

A great place to find where a lot of the deals are is Leaseloco and there are many websites like it. Also this chap’s regular YouTube channel gives you a heads up on what’s around. I have also listed some other YouTube channels below.

So in summary, if you find a good deal you have to act very quickly. Hence the necessity for sending the car back early.

I also think in this context that the Tesla Model 3 is probably better value than the Model Y at the moment but then again Tesla change their prices at the drop of a hat, another reason for leasing rather than buying.

Will my next car be a Tesla?

Sorry to my Tesla loving friends but the answer is no and here are the reasons why

- There’s a lot more competition in the market than there was three years ago and many of the other manufacturers have caught up with the tech

- The constant penny pinching, particularly regarding the driver interface, I find grating. As an engineer I respect seeing good design and clever ideas. Whilst this is very much the case with the software side of the car, the mechanical side is being driven by cost and not quality. The ridiculous buttons on the steering wheel on the Model 3 instead of an indicator stalk takes the biscuit.

- The car is costed as a quality car- cheaper cars now have better build quality and extra functionality and are thus far better value for money. Just look at this car currently available in China but on the way to Europe in a couple of years and priced around $35000. It took 200000 orders in less than an hour when it was launched in China.

- Tesla don’t seem to be interested in cars anymore. They’ve wasted so much money on the truly hideous Cyber Truck when they could have built an entry level car instead. They are in huge trouble in the Chinese market where domestic cars are cheaper and arguably better.

- I probably would have stayed with Tesla but the whole ‘political thing’ made me look at alternatives. One of my mentors once told me the best way to p**s someone off was to start an assault on their values.

- Tesla’s values seem to have changed from being a brand that was going to help the world move to a more sustainable future, to a company obsessed with ‘robotaxis’ (why not ride a bike or get the bus/tube?) and humanoid robots. To me that means a reduction in R&D and product improvement in their automotive business just when the competition is investing more.

I suppose that the question I haven’t answered is will my replacement car be an EV?

The answer is of course yes.

The benefits of cheap running costs, easy driving and a great ownership experience mean that I would never go back to an ICE as my daily transport. I think that in twenty years time filling a car with petrol will be looked upon as the equivalent of feeding hay to a horse. I would add that I do have a forty year old classic but that usually does fewer than 1000 miles a year. I think electrification will be that vehicle’s fate in the future too.

I think if some of my frustrations with the company were addresses then I would consider another Tesla in the future. The leadership of the company need to get back to what they were originally trying to achieve.

So, when I’ve put a few miles on the new car replacing the Tesla, I will give a verdict and I will find out if I’ve been wrong!

Thanks for reading. Please leave a comment here or on the LinkedIn post that directed you here. I’m always eager to learn if my opinions resonate or jar!

Here are the links

- https://www.youtube.com/@whatcar

- https://www.youtube.com/@carwow

- https://www.youtube.com/@RyanShawtech

- https://www.youtube.com/@JustGetATesla

- https://www.youtube.com/@Electrifyingcom

- https://www.youtube.com/@TimRodieDrivesStuff

- https://www.youtube.com/@Autotrader_uk

- https://www.youtube.com/@AutoEV

- https://www.youtube.com/@CarGurusUK

- https://www.youtube.com/@RSEV

- https://www.youtube.com/@fullychargedshow

Starting out on the NED Journey

Quite a few people have approached me over the years to seek out my advice about how to create a successful portfolio career. I wouldn’t say that I am the best example of how to do it but I have enjoyed working with a mixed portfolio over the last 15 years or so.

Originally I set out to have a mixture of NED and advisory roles for paid work and policy and charity/not for profit roles on a pro-bono/expenses only basis.

I would add that most of my work has been within private companies or not-for-profits so that may have influenced my outlook. Additionally I have also worked in advisory roles to professional services firms which is very different to NED work.

The majority of people that have sought advice are still in an executive position and wish to explore their options. Others have faced the axe of a corporate restructuring and feel that the chances of gaining another executive role that matches the package that they have lost is very slim. Some have retired and don’t want to stop working. Some people have the right skills, experience and network and glide into NED roles. For others it’s more of a challenge. Additionally some are more of a cultural fit than others.

Whatever the circumstances that you are in here are my top twenty tips, I hope that they are useful.

- Unless you are either well funded or in a supportive relationship and your partner is in full time employment, you will never have the job security of a full time job. If this concerns you then don’t give up searching for the full time role. Even when you become a NED, it’s always worth remembering that these roles will never be a permanent.

- Start the process of working in a NED/Trustee position as early as you can. Charities and Not for Profits need good people on their Boards. It’s unremunerated but you will learn a lot about the NED perspective, work with some great people outside of your working environment and feel that you have made a difference. Your employer should also be happy to support you doing this. I would advise working with a charity which has a cause with which you identify with otherwise it could become a chore. I spent 15 years doing this before I went plural and continue to do so. Getting a place on an Advisory Board is also a good way to feed in to more committed NED work. Also consider giving some mentoring to people outside of your business. As part of this process you will start to wean yourself from the executive to non-executive mode of working and gain that essential perspective.

- Go get some training– there are very good NED courses out there, I have completed several. They will give you a sound appreciation of what to do and how to manage situations. The IoD NED course is a good one. The Big Four accountancy firms’ NED networks also have a treasure trove of supporting information and content.

- Set up your own company to facilitate your work. Most private companies will be hesitant about adding new people to the payroll, particularly if they haven’t appointed NEDs before. I went full ltd company and VAT registered but some will just wish to be a sole trader. Get accountancy support if you need it.

- To find positions, maximise your network Make the most of professional networks you are involved in, it could be a trade body, membership organisation or a professional body. Make sure that you are actively engaged and working with people.

- Attend events, get out and about and do stuff, go the extra mile and attend events. I tend to go to things that will inform and educate me- I like to leave the event having learned something (this adds value to your NED capabilities too) I prefer these sort of events to purely networking ones, as you are with people who can sit down and listen to something for an hour! (I’ll write a blog about this soon). If you are invited to an event, then turn up and attend- no shows and late cancellations cause all sorts of pain to the person who has gone out of their way to invite you.

- Use social media to full effect I tend to use LinkedIn for a whole variety of things

- It’s my CV for everyone to see and browse

- It’s a mobile contacts book which never goes out of date

- I can learn about what’s going on

- I can post things of interest to folks (I like my posts to be either interesting or informative)

- My network knows about current things I am doing or involved with and that I’m active

- I can comment on and share interesting posts

- I can help people and repost job vacancies that I think people in my network might be interested in. It supports them and the person in my network with a vacancy- it’s a no brainer

- I only connect with people who I have met face to face or have some sort of work related or correspondence with (each to their own and I know others accept all invitations. My personal view is I don’t want my connections to be spammed by those spamming sales stuff or just gathering connections for databases)

- Job applications – lots of jobs out there! My only tip would always make sure that you are a good fit for the role and tune your CV- good luck!

- NED introduction agencies, I have been approached by several of these organisations and networks but have never used them. If you feel that you need that sort of help and can fund it, it may be worth a go. I would advise treading carefully as they usually can’t guarantee outcomes.

- Headhunters, Most headhunters are very helpful with advice on applications and evaluating your CV, share updates with them.

- Referrals Most, if not all of my roles, have come from referrals. If your colleagues and network feel comfortable with you and confident that you won’t let them down, then to me that’s the greatest compliment I can get. If you can give referrals for others in your network that will help them and you, again a no brainer! Also giving out LinkedIn recommendations is a great way of supporting your network.

- Beware the ghosters! It seems to be a British disease that some folks can’t tell people that they aren’t wanted. After several meetings/interviews suddenly everything goes quiet and no replies to calls are forthcoming. If you get into this situation, it’s best to cut your losses, mark it down to experience and move on. Don’t fill up your pipeline with stuff that isn’t going to happen.

- Get some mentors– talk to people you know, respect and trust. They will understand you and what you are trying to achieve and will give you their unfettered opinions and advice. Getting a b********g for using a typeface on my CV that was impossible to read and some choice words for even considering a Chair role at an AIM listed business that was probably a basket case, are just two examples which spring to mind. My ears are still ringing but the advice was invaluable.

- Once you have found a position do your due diligence on the company– I am amazed at the pickle some folks get themselves after finding out what’s really going on in the business, if in doubt have a chat with your mentors about it for their opinions. Look for a things like a constant stream of Directors being appointed and then leaving and also strange things within the finances. Pretty obvious but many forget to do this. Make sure that the company can afford you. You don’t want to be in a position of chasing debts.

- Listen to what the prospective company wants. Some just want mentoring and advice so don’t get hung up about being on the Board. Just make sure that the role is purely advisory and would not be construed as being a Shadow Director. Also remember that you are not executive!

- Get yourself a standard contract and work out day rates to get things going. I usually work for a monthly fee based around a certain number of days. It helps me to budget and means the company paying you doesn’t have any unpleasant spikes to cope with. If after a few months you are doing more or less time it can be adjusted. Run the contract past a litigation, sorry, ‘dispute resolution’, lawyer if you know one.

- Governance- always refer back to your training when in a NED position. Constantly be on the lookout for things like conflicts of interest, not minuting meetings, poor risk management and anything that is simply not right. In the end as a NED your only real sanction is to resign but you must always do the right thing.

- Educate yourself and keep up to date– companies expect their NEDs to be fully up to speed on all sorts of things, particularly geopolitics at the moment. Make sure that you are well read and also know individuals who can help out by sharing their knowledge too. There are lots of online webinars around which can help. Judging business awards is another way of learning through reading about other business leaders’ journeys.

- Serendipity If you do all or some of the above you are significantly improving your chances of having a successful portfolio career. Serendipity always plays its part, making connections and then things happening from those connections. One thing for sure, if you do nothing then nothing will happen!

- The most important point- Always Pay Back and Forward! if someone has gone out of their way to help you and given up time and effort then see what you can do for them. Also, if you can, try and help those that maybe are too shy or timid to reach out. Everybody needs a helping hand at some point in their life.

If you have found this helpful or if you think it’s tripe, then please comment below or better still comment on the originating post on LinkedIn.

If you are feeling very generous please repost my LinkedIn post to your network and see what they think about it. It will remind your network that you are looking for NED roles too.

Recent Interview concerning sustainability in Manufacturing

Recently I was asked by the team at New Street Consulting for my perspectives on the issue of how manufacturers can operate more sustainably.

Here’s the interview and you can find the article here

We’re thrilled to have had the pleasure of speaking to David Seall, a highly respected Chartered Engineer, non‑executive director, and manufacturing specialist with over 20 years of board-level experience.

David combines deep technical expertise with strategic insight, advising SMEs on growth, succession planning, M&A, and lean manufacturing strategies. He is also a Visiting Professor at the University of Surrey Business School and contributes to key industry initiatives, including the AllParty Parliamentary Manufacturing Group and the Manufacturing Commission.

Gavin Wingfield spoke with David as he shared his unique perspectives on manufacturing innovation, sustainability, and leadership in an increasingly complex world.

WHAT ROLE DOES SUSTAINABILITY PLAY IN YOUR OVERALL BUSINESS STRATEGY?

I think sustainability is an essential part of a modern business strategy. Many people still see it as a “nice to have,” or worse, as greenwashing to boost their business image. But when done properly, it should deliver a return on investment and make the business more efficient.

As someone who has advocated for lean manufacturing for many years, I believe the sustainability agenda aligns closely with lean principles. In manufacturing, you’re constantly looking for ways to reduce waste, and much of that waste reduction also leads to cost savings. When sustainability is approached this way, it becomes a strong driver for improvement.

Take Toyota’s lean philosophy, for example. One of the key principles is using fewer materials, which is inherently more sustainable. If you can source those materials sustainably, especially biosourced, recycled, or reused materials, it reduces waste at both the input stage and through reapplication. Reducing energy consumption is another clear benefit. Transitioning from fossil fuels to electrification and improving the efficiency of energy use and goods transport are all meaningful steps.

Another important aspect of sustainability lies within the business culture itself. Employees, especially younger generations view sustainability as a core value. Companies that embrace it are seen as doing the right thing, which enhances their reputation and makes them more attractive places to work.

Ultimately, businesses that actively pursue sustainability can clearly demonstrate how they contribute to the broader goal of a more sustainable manufacturing sector.

WHAT INVESTMENTS ARE YOU SEEING IN GREEN TECHNOLOGIES AND/OR SUSTAINABLE INNOVATION?

I think there are a few obvious examples that come to mind, such as investing in on-site solar power generation and electrifying the company’s transport fleet. These are no-brainers and complement each other well. We can also talk later about other technological investments, like capital equipment, that support a more sustainable business.

However, one of the most critical areas of investment is ‘skills’. This poses a major challenge for the manufacturing sector, as the skills needed to build and maintain a sustainable business are in high demand across all industries, not just in manufacturing. Retail, financial services, and many other sectors are competing for the same talent. So the challenge is twofold, developing a skilled workforce and continuing to invest in and retain that talent over time.

WHAT SPECIFIC ACTIONS CAN LEADERS TAKE TO REDUCE ENVIRONMENTAL IMPACT?

I think a lot of this goes back to lean manufacturing. Obvious examples include reducing inventory, reducing overproduction, making only what you need, and investing in additive manufacturing. With additive methods, you’re producing net-shaped parts without tooling and only making the part when it’s actually needed.

There also needs to be a major effort toward recycling and reuse to support a circular economy, along with designing products that are repairable. The right to repair legislation in the EU highlights this, but it should be central to how we think about the products we make. How can these products be repaired and kept in use?

Over the past 25 to 30 years, we’ve seen a shift toward single-use items and a disposable culture. But I’ve visited factories with equipment still running after more than 60 years simply because it’s easy to fix, and it still does the job well. In some ways, we need to return to that mindset.

It reminds me of the old “Trigger’s Broom” analogy or even the Dualit toaster, where every part can be replaced, from the timer to the heating elements. I’ve had a Dualit toaster myself, and the only original part left is the casing. Everything else has been replaced over time, but it still works perfectly.

We need to move away from throwing things away unnecessarily. There’s a powerful statistic about mobile phones: a tonne of mobile phones contains more gold than 100 tonnes of gold ore. That comparison really puts things into perspective.

WHAT ARE THE BIGGEST CHALLENGES ORGANISATIONS FACE IN IMPLEMENTING SUSTAINABILITY INITIATIVES?

Short term pressures are a major factor. Sustainability is a long term objective, and short term issues often get in the way. As we’ve seen over the past year, the rise in National Insurance costs and ongoing pressures on energy prices, where electricity is four times more expensive than gas, really do not make sense. That cost structure needs to change if we want to incentivise electrification. But these issues impact cash flow and create real barriers for businesses.

I also think there’s an increasing need for resilience and security in the supply of raw materials and components. This has become more difficult due to trade barriers, logistical challenges, and the movement of goods globally. One of the key challenges businesses now face, and I will probably mention this again, is how to reduce complexity and reshore supply, whether that is back into the United Kingdom, mainland Europe, or simply somewhere closer. The goal is to create a more resilient and sustainable supply base.

HOW DO YOU INTEGRATE SUSTAINABILITY INTO YOUR SUPPLY CHAIN DECISIONS?

This largely comes back to supply chain security rather than just cost. In the past, many focused on price and overlooked transport costs. When shipping prices surged post-COVID, businesses realised the high cost of moving goods from places like China. This supports the sustainability agenda by encouraging local production closer to demand, reducing both costs and environmental impact.

When OEMs localise, the supply chain must adapt. Thirty years ago, large OEMs avoided UK suppliers unless they sourced heavily from Eastern Europe or Asia. Now, the priority is resilience and the ability to respond quickly to short term challenges. Supply chains must be more integrated and less stretched. It may not be the end of globalisation, but it’s a clear shift toward more localised, sustainable models.

HOW DO YOU INCENTIVISE SUSTAINABLE PRACTICES WITHIN YOUR COMPANY OR AMONG PARTNERS?

Much of this starts with establishing a baseline, understanding where you are now, then tracking the impact of your efforts. Like any lean or continuous improvement program, you begin in a less than ideal state and show progress to employees, making it clear how changes affect them. This can include encouraging reduced material use and waste, and demonstrating real time data, such as energy produced by rooftop solar panels.

Seeing tangible results, like a factory running entirely on solar power, can be a major morale boost. It helps employees understand the purpose behind sustainability efforts. Promoting recycling, reducing scrap, and offering incentives, possibly financial, are effective ways to build engagement. The same applies to suppliers, collect data on their energy use and resource efficiency. That’s what real supply chain management looks like.

HOW DO YOU STAY AHEAD OF REGULATORY OR CONSUMER EXPECTATIONS AROUND SUSTAINABILITY?

I think that’s a tough one. The phrase geopolitics comes up more and more when talking about what’s happening in the world. The days of just coming in on Monday, doing your job, and leaving on Friday are gone because many external factors now influence businesses, whether regulatory or financial, such as taxation or new regulations. You have to stay ahead of the curve and know what’s coming.

A big part of this is staying close to your customers, understanding what pressures they face and what they might be planning. Also, being part of trade or employers associations like Make UK is invaluable. These groups have policy experts who can give you a heads up on what’s ahead. I’ve seen this from both sides, working within such organisations and as a member, and it’s incredibly helpful to get briefed by people who know exactly what’s going on and what’s coming around the corner.

While some things can still be surprises, most should not be, as they’re usually discussed for some time. Trade associations are often consulted by the government before new policies are introduced. They assess whether proposals are feasible or problematic. The Treasury does similar work. Staying connected and informed means these developments shouldn’t come as a surprise.

WHAT ADVICE WOULD YOU GIVE OTHER COMPANIES JUST STARTING THEIR SUSTAINABILITY JOURNEY?

I would say first, do not see this as a cost. Many people think it’s just something they have to pay to be sustainable. It shouldn’t be a cost, if done properly, it delivers benefits to your business including cost savings, lower prices, and making you a better company.

Start with the low-hanging fruit. For example, if you have a south-facing roof, install solar panels, move your fleet away from diesel and petrol vehicles if possible, or incentivise staff to switch to electric vehicles through leasing deals. These are easy wins.

Embed sustainability into your continuous improvement and lean programs so it’s part of your normal operations, not an extra task. Things tend to fail when seen as additional work. If it’s built into your regular reporting and monthly measures, it will be sustained and continue.

Also, look at the bigger picture of your sustainability journey as a manufacturer. Consider how you can be involved in the entire product lifecycle. This leads to servitisation, where you add value through services rather than just delivering products. This creates a complete sustainability circle and helps you fully understand the impact of your activities.

CONCLUSION

Thank you to David Seall for sharing his valuable insights and deep industry knowledge with us today. His experience at the forefront of UK manufacturing, combined with his strategic perspective on innovation, sustainability, and leadership, offers a powerful reminder of what it takes to drive meaningful progress in our sector.

We hope this conversation has sparked new ideas and inspired you to think differently about the challenges and opportunities ahead.

Switching off

Friends and colleagues often ask me why I still have a ski break during the winter with all of the risks of injury etc (especially at my age is usually the next line).

Without doubt it’s an expensive holiday, is probably an indulgence and of course there’s the underlying risk of an accident.

However I have found it does have a lot of benefits to my working life.

Obviously all of the pre-holiday work outs to get fitter during the winter can’t be a bad thing and it certainly helps to have a target date to focus those efforts.

I think the main benefit to me, as with all activity based holidays, is that it gives you the opportunity to completely switch off from work. There’s no room to be distracted when one is concentrating on navigating the slopes. Probably exacerbated by my technique too!

One thing always is always on my mind though. A much missed colleague once told me never to try and keep up with your children once they get to adulthood as that can only ever have a bad ending!

Recent Comments